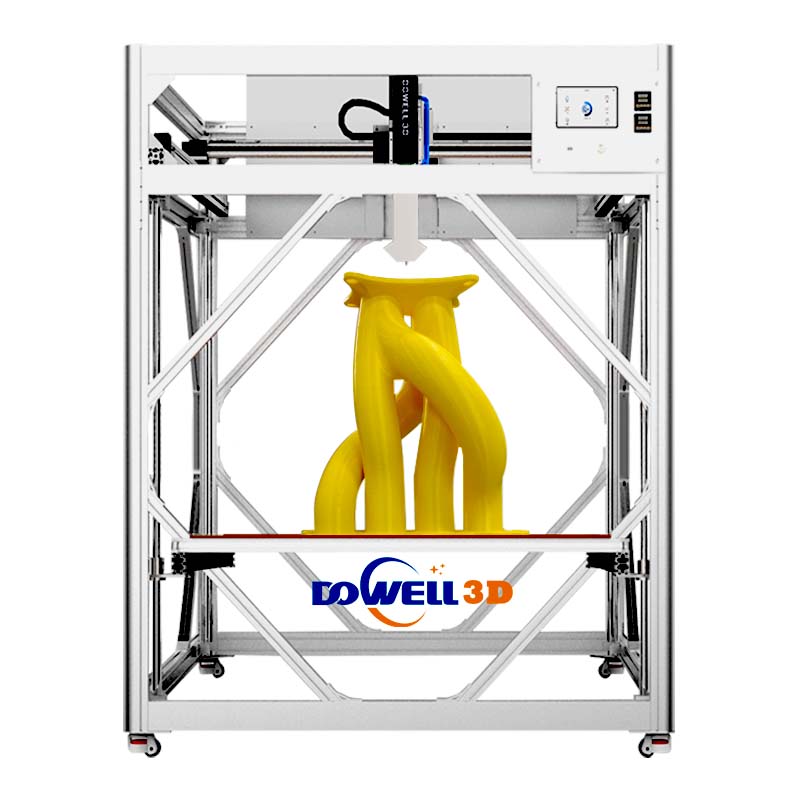

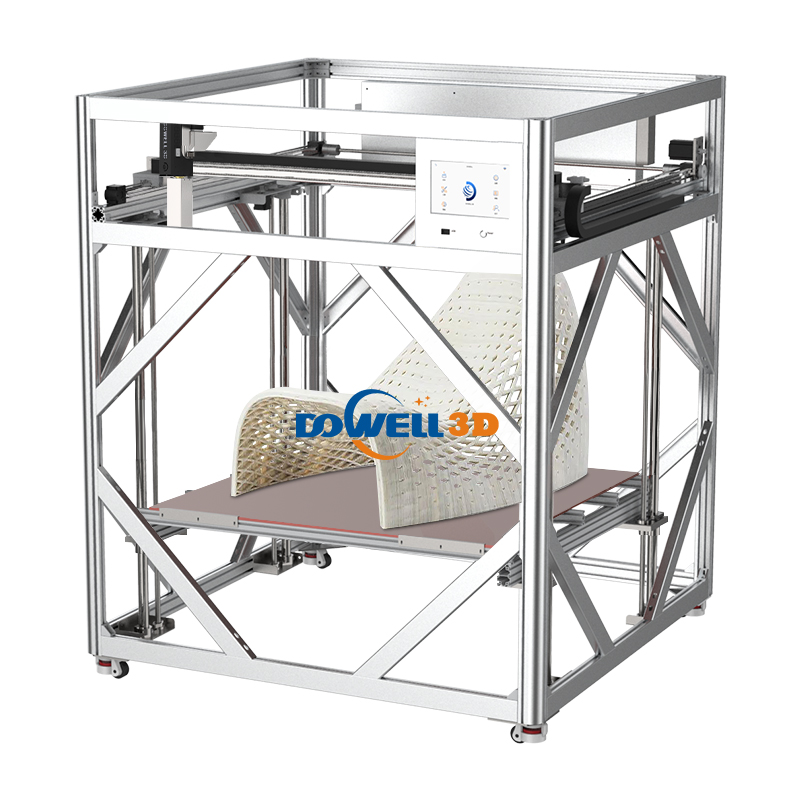

Imprimantă 3D Dowell la scară largă cu peleți, mașină de imprimare 3D industrială cu particule de plastic

- Dowell 3d

- China

- 10-16 zile

- 1000 seturi/m

Imprimanta 3D cu peleți Dowell3D utilizează materii prime pe peleți termoplastici eficiente din punct de vedere al costurilor, asigurând o producție de mare viteză.

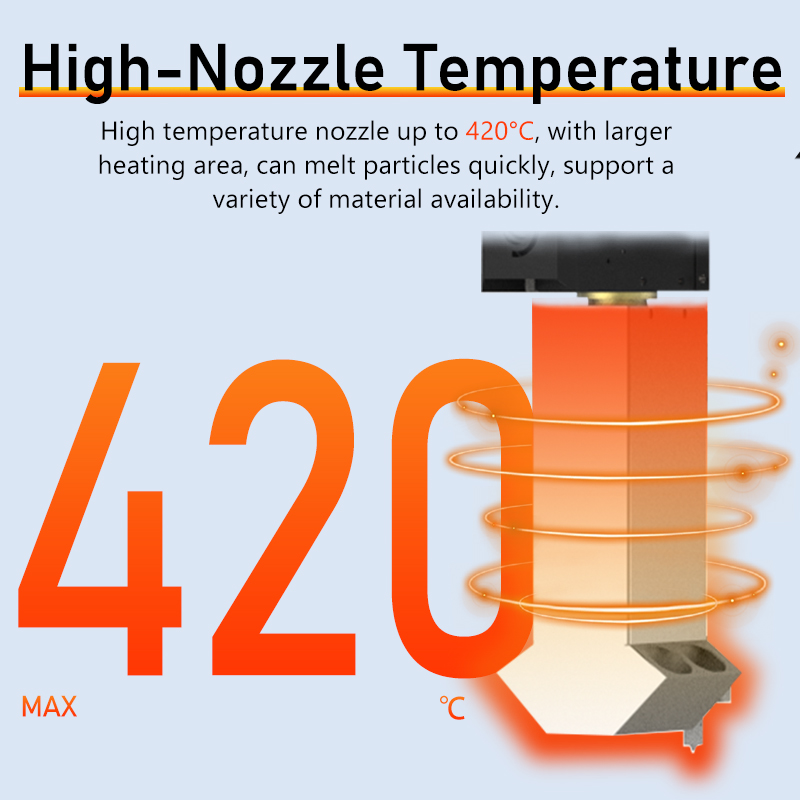

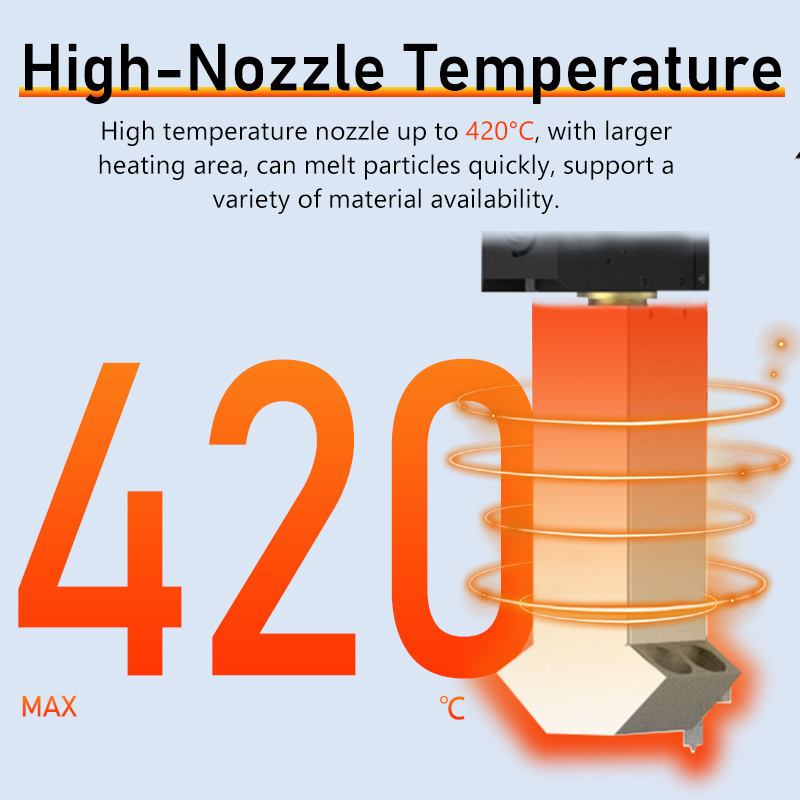

Temperatura duzei până la 420 ℃

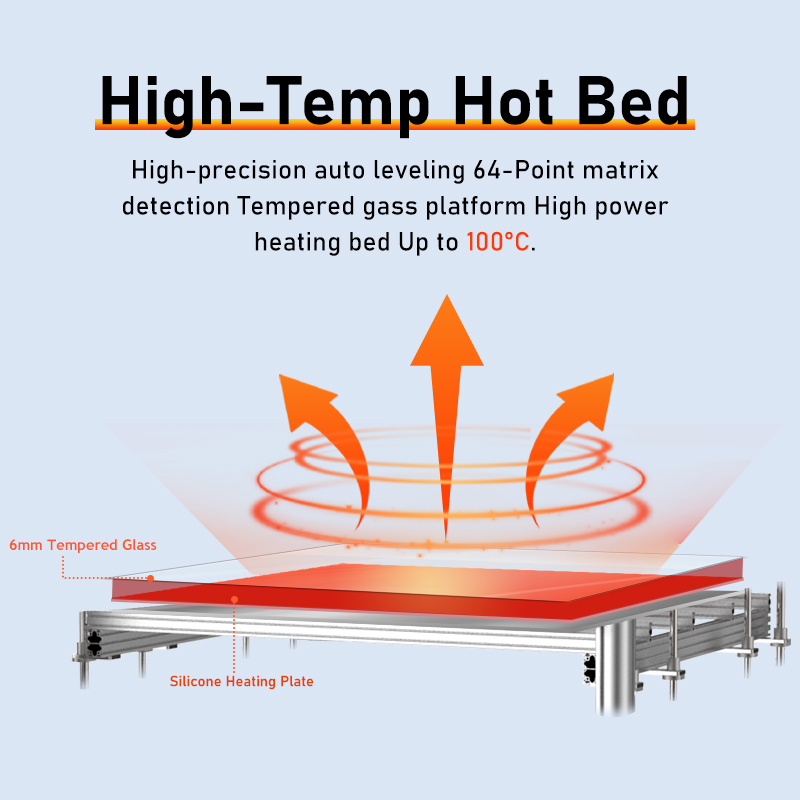

Încălzire rapidă a patului fierbinte până la 100 ℃

*Extrudare cu șurub cu debit ridicat

Controlul temperaturii în 3 etape

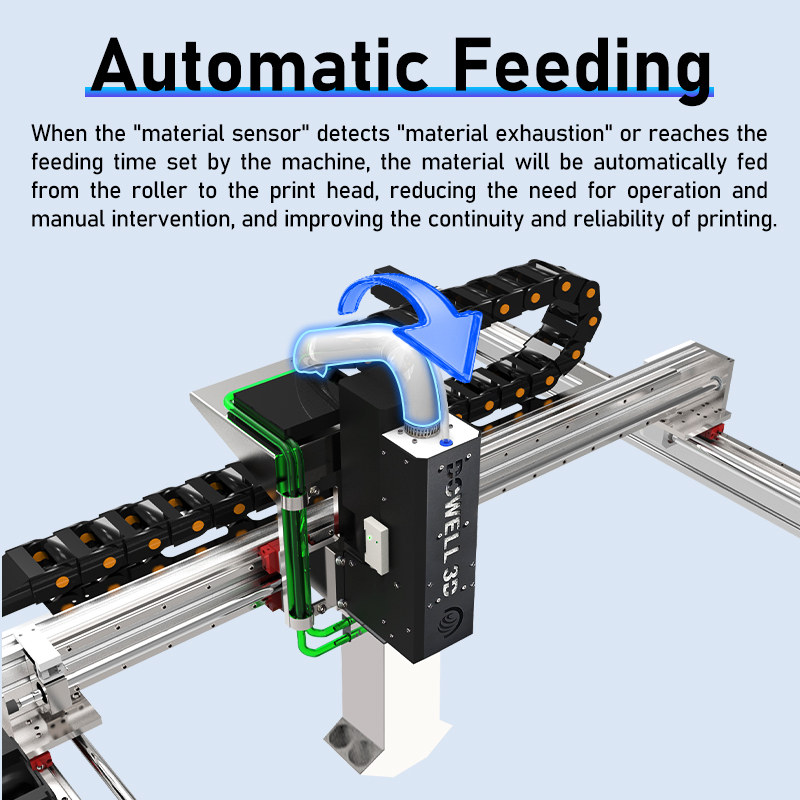

*Sistem automat de alimentare

DOWELL3D

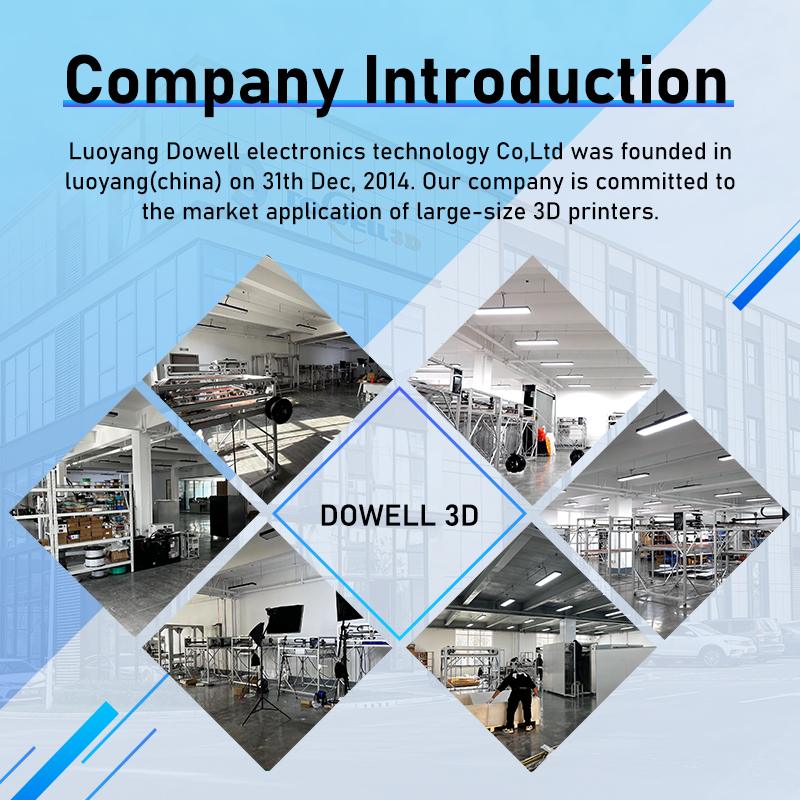

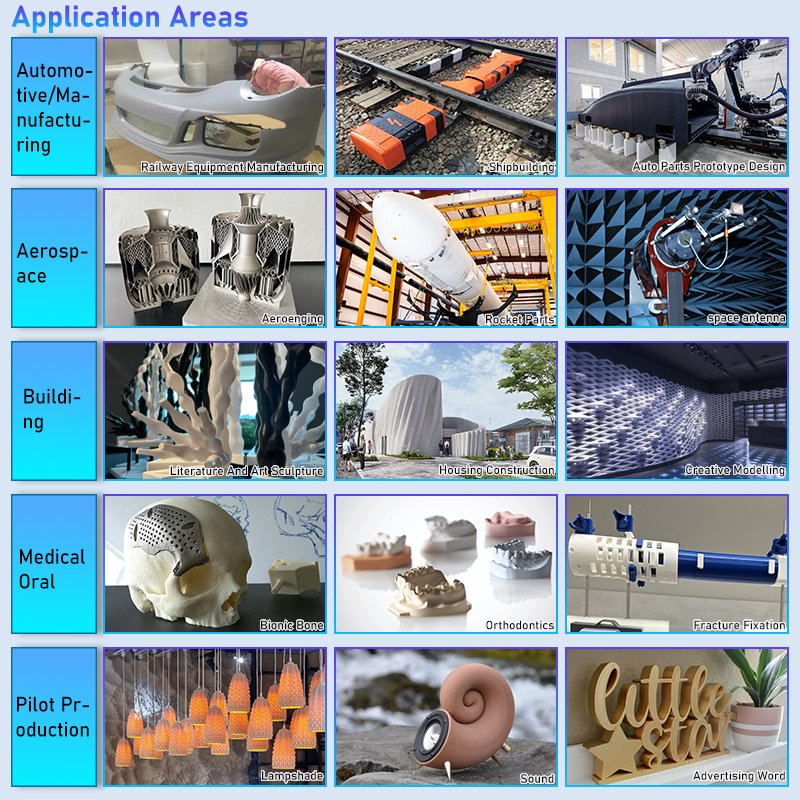

Dowell este o companie axată pe tehnologie, dedicată inovației și dezvoltării durabile, specializată

în furnizarea de filamente pentru imprimare 3D de înaltă calitate și ecologice, precum și de filamente industriale de format mare

Imprimante 3D.

Aceste produse includ echipamente specializate, cum ar fi imprimante pentru sculptură, imprimante auto, imprimante cu pelete,

și imprimante pentru mobilă. Soluțiile companiei sunt utilizate pe scară largă în industrii precum cea auto, aerospațială,

biomedicală, semnalizare publicitară, fabricare de matrițe, design de mobilier și producție de sculpturi.

Imprimante 3D cu peleți FGF de calitate industrială

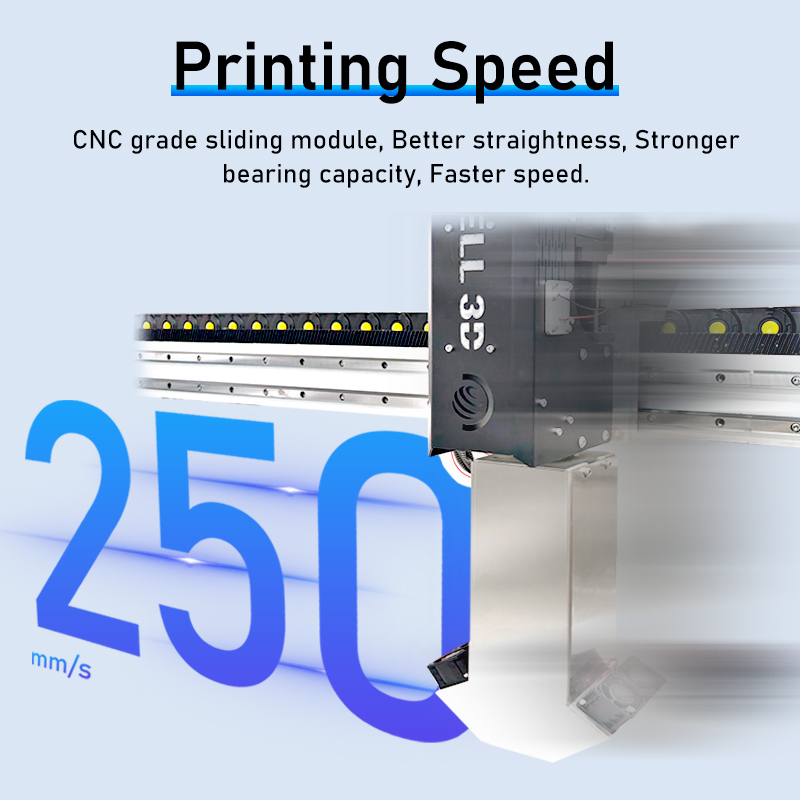

Imprimanta 3D cu peleți Dowell este o imprimantă de extrudare termoplastică de format mare și mare viteză, cu o capacitate maximă

debit de extrudare de până la 5000 g/h și o viteză de imprimare de 250 mm/s. Poate imprima rapid fără așteptare,

iar duza poate fi încălzită la 420°C în 35 de secunde, economisind timp prețios.

Este potrivit în special pentru crearea de modele, matrițe, scule, dispozitive de fixare, dispozitive de fixare de dimensiuni mari, serii de producție în serie și

prototipuri la scară completă.

Dacă doriți să aflați mai multe despre informațiile despre produs și prețul imprimantei 3D cu particule FGF DP-A,

Vă rugăm să faceți clic pentru a consultași vom avea consultanți profesioniști în materie de produse care să vă răspundă la întrebări.

| Nume produs | Imprimantă 3D industrială cu peleți FGF |

| Tehnologia de turnare | Fabricarea granulelor topite (FGF) |

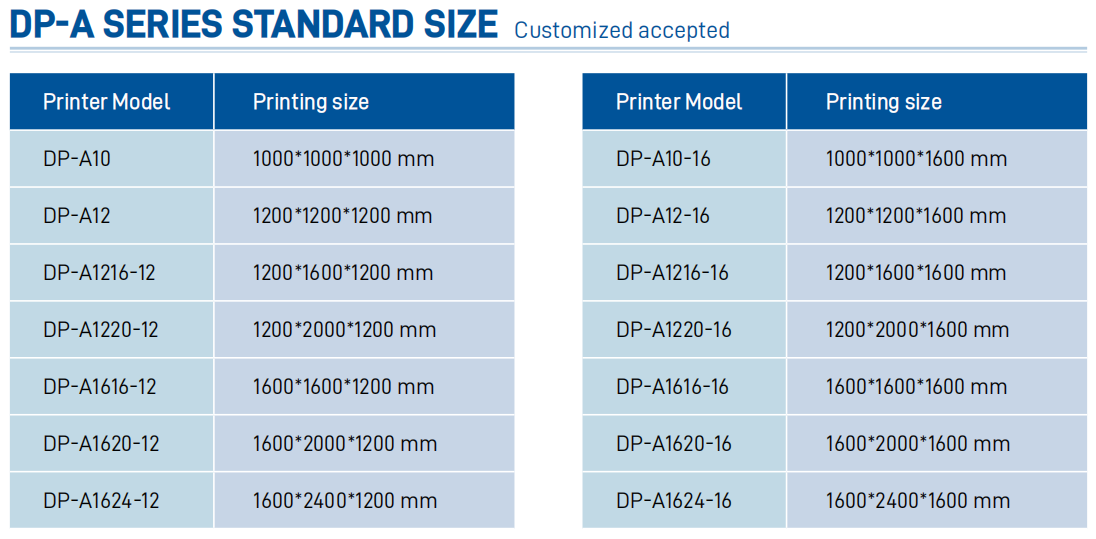

| Dimensiunea turnării | De la 1000 * 1000 * 1000 MM la 1600 * 2400 * 1600 MM (personalizarea este acceptată) |

| Cadru | Secțiune de aluminiu îngroșată de 80 mm |

| Sistem de alimentare | Alimentare automată |

| Temperatura patului | Sticlă securizată de 6 mm 0-100 ℃ |

| Material de imprimare | peletă <Φ4mm recomandată |

| Diametrul duzei | 1,0/2,0/3,0 mm |

| Extruder | Extrudare cu șurub în 3 etape, sistem de alimentare automat |

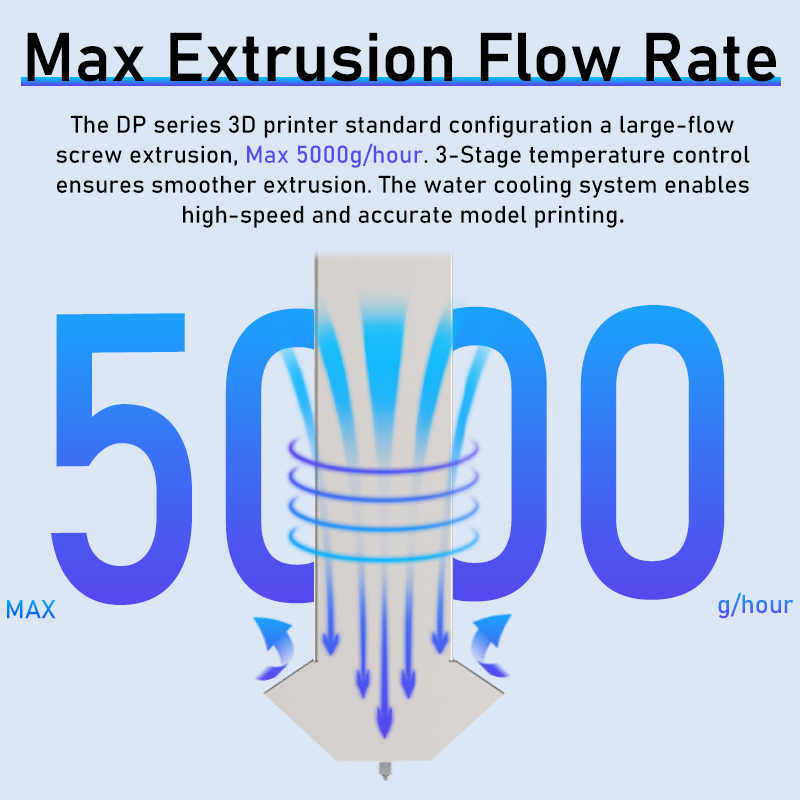

| Debit maxim de extrudare | 4000-5000g/oră |

| Viteză de imprimare | 0-300 mm/s |

| Sistem de răcire a extruderului | Răcire cu apă |

| Temperatura duzei | 0-420℃ |

| Interfață de operare | Ecran tactil color de 10'' |

| Formatul fișierului | STL/OBJ/GCODE/JPG |

| Putere de intrare | 110V/220V |

| Funcții de bază | *Nivelare automată *Telecomandă *Osistem automat de alimentare *Răcire cu apă *Conexiune Wi-Fi *Stare imprimare vizibilă *Grafic de temperatură vizibil *Cameră externă instalabilă *Configurație editabilă *Reglare decalaj Z *Reglarea vitezei, extrudării și răcirii *Vizualizator Gcode *Înregistrare istoric *Buton de oprire de urgență *Control automat al temperaturii |

| Opțiuni de personalizare | *Carcasă la 60°C *Dimensiune imprimare |

Descriere produs

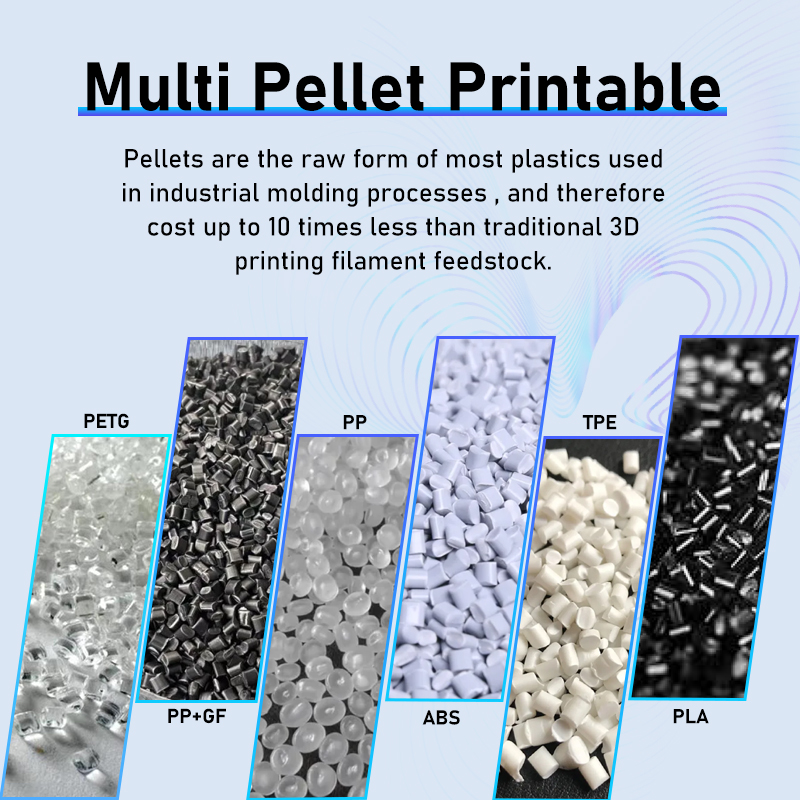

Diverse materiale pentru peleți disponibile

Peletele sunt materia primă pentru majoritatea materialelor plastice utilizate în procesele industriale de turnare. Imprimantele noastre din seria DP-A

creează condiții excelente pentru imprimarea pe pelete, permițând încălzirea și extrudarea rapidă a materialelor, de la

PLA către termoplastice de înaltă calitate pentru temperaturi ridicate. Acest lucru oferă un suport puternic pentru imprimarea industrială pe pelete compozite.

Extrudare cu șurub cu debit ridicat

DP-A dispune de un sistem de extrudare cu șurub inovator, revoluționând imprimarea 3D de format mare cu puterea sa puternică,

forță de extrudare uniformă pentru un flux uniform de material și aderență. Oferă grosimi de felii și dimensiuni versatile ale duzelor

(1,2-3,0 mm), permițând atât detalii fine, cât și debite mari (până la 5000 g/h), îmbunătățind calitatea și flexibilitatea imprimării.

Duză de înaltă temperatură 420℃

Cu o temperatură a duzei care atinge până la 420°C și o temperatură a patului de ≤100°C, DP-A FGF Pellet 3D

Duza imprimantei este concepută pentru a manipula materiale la temperaturi ridicate. Acest lucru permite imprimantei să lucreze cu o gamă largă

o gamă largă de materiale termoplastice și compozite, inclusiv PLA, PETG, ABS, TPE și materiale compozite,

lărgind orizontul pentru crearea cu ușurință a unor piese durabile și complexe.

Platformă de încălzire excelentă și stabilă

Placă de încălzire din silicon + platformă din sticlă securizată de 6 mm

Întreaga suprafață a platformei utilizează o placă de încălzire din cauciuc siliconic pentru o încălzire uniformă și rapidă, reducând timpii de așteptare pentru imprimare.

Controlul precis al temperaturii de la 0 la 100°C previne eficient deformarea și se mândrește cu o capacitate portantă ridicată.

depășind sute de kilograme.

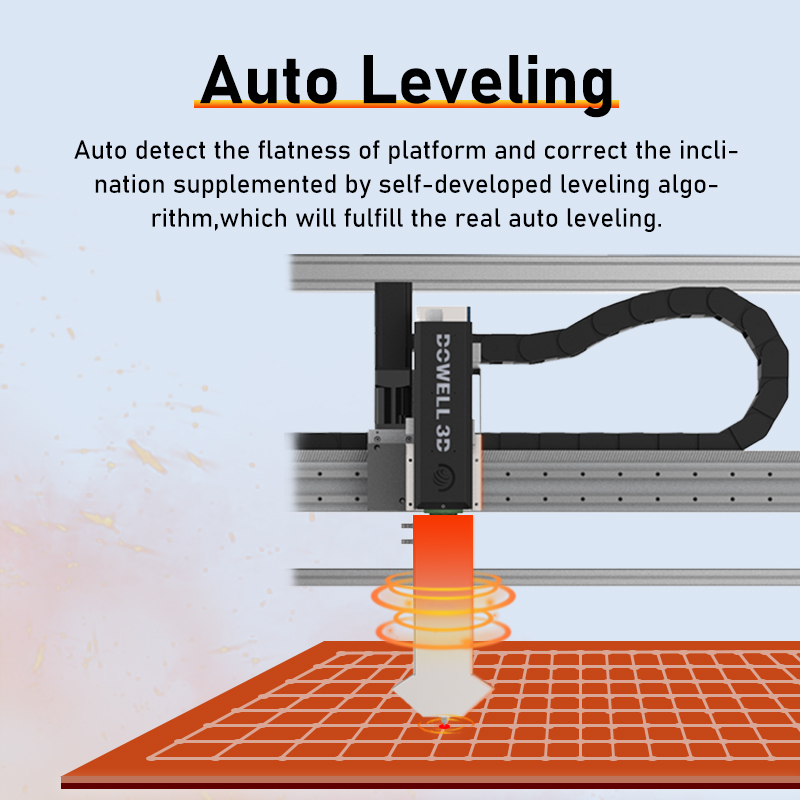

Nivelarea automată cu o singură tastă vă ajută să operați cu ușurință

Imprimanta 3D DP-A Pellet dispune de un sistem de autonivelare bazat pe senzori de înaltă precizie.

Permite duzei să detecteze automat înălțimea platformei. Algoritm în timp real

Ajustările fac procesul de imprimare ușor și convenabil.

Alimentare automată

Când senzorul de material detectează epuizarea materialului sau atinge timpul de alimentare setat de mașină,

Materialul va fi alimentat automat de la rolă la capul de imprimare, reducând nevoia de operare și de utilizare manuală

intervenție și îmbunătățirea continuității și fiabilității imprimării.

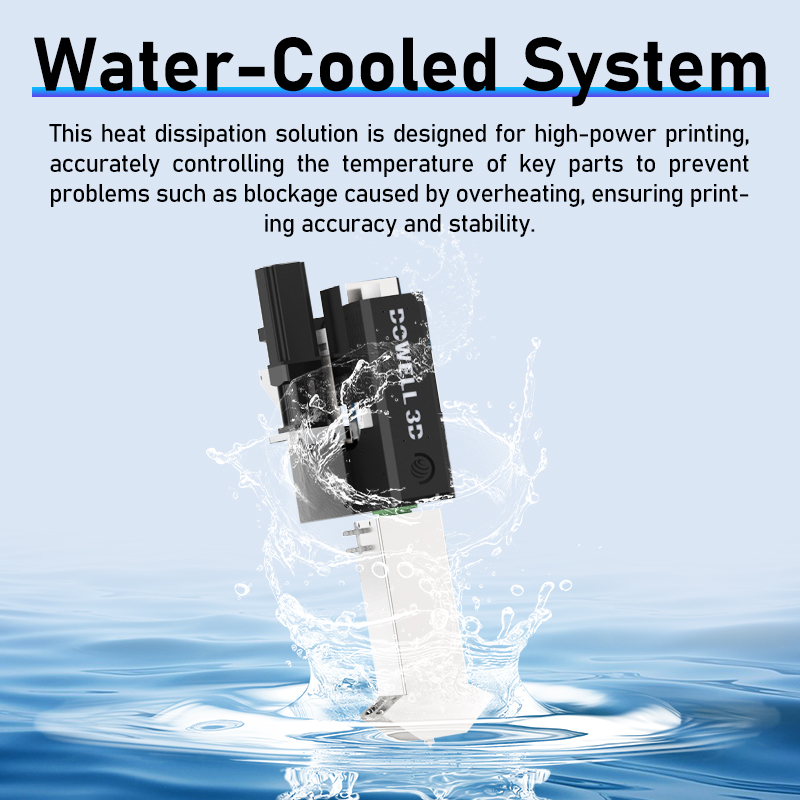

Sistem răcit cu apă

Această soluție de disipare a căldurii este concepută pentru imprimare de mare putere, controlând cu precizie temperatura

componente cheie pentru a preveni probleme precum blocajele cauzate de supraîncălzire, asigurând precizia și stabilitatea imprimării.

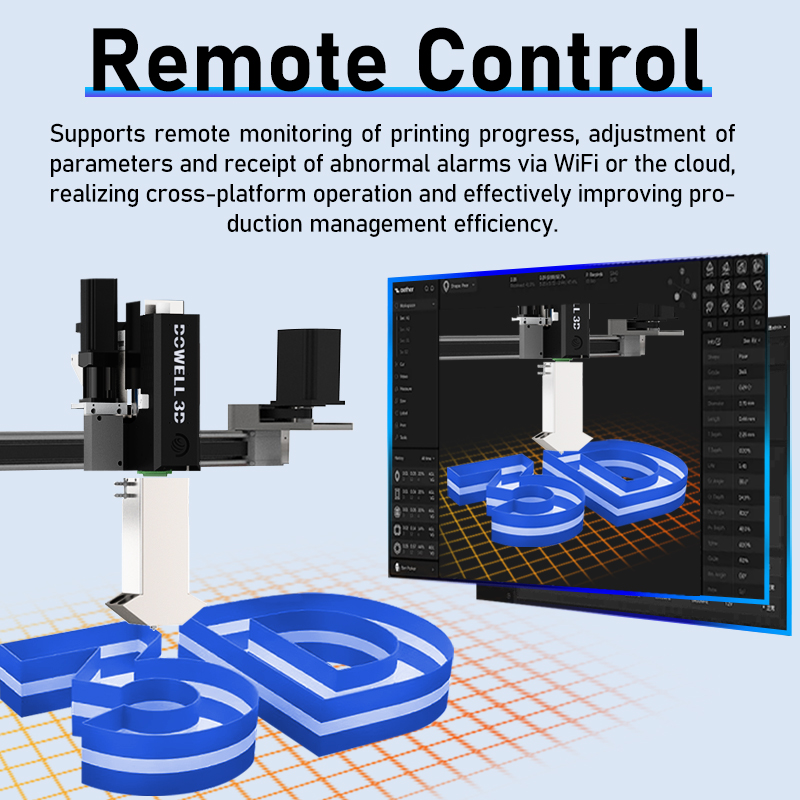

Conectivitate WiFi și telecomandă

Conectați-vă de la distanță la imprimantă, imprimați fișiere direct și monitorizați starea imprimării în timp real, facilitând astfel imprimarea.

mai ușor și mai convenabil. Tehnicienii se pot conecta, de asemenea, de la distanță la imprimanta dvs. pentru actualizări de sistem și

întreținere. Simplificați imprimarea.

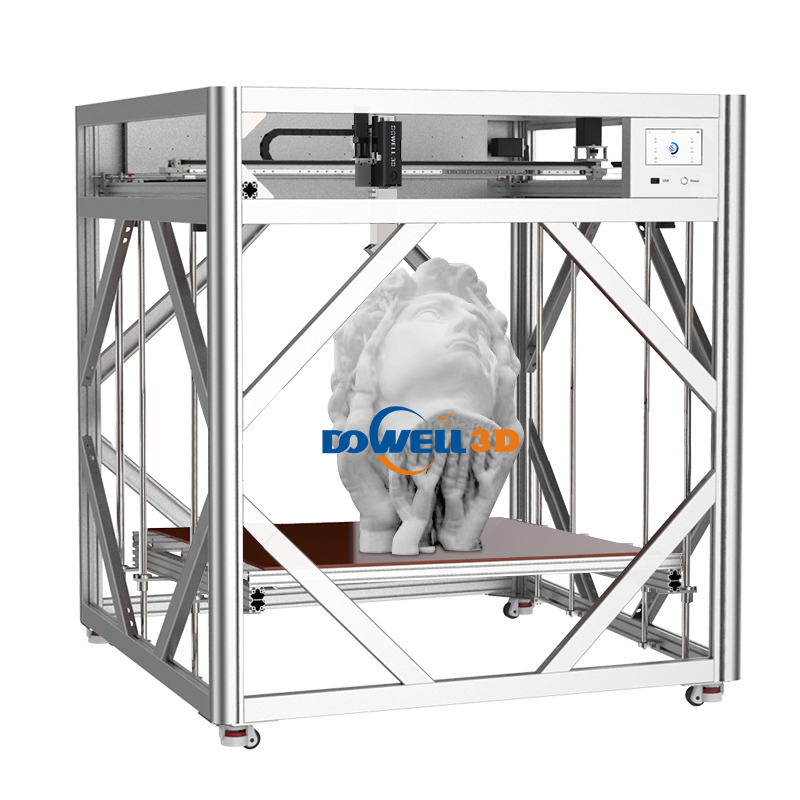

Spațiu de lucru mare

Imprimanta 3D cu peleți DP-A se mândrește cu un spațiu de lucru mare, cu dimensiuni de până la 1600 x 2400 x 1600 mm, oferind un spațiu amplu...

spațiu pentru producerea unei varietăți de piese de dimensiuni mari.

Zona de construcție spațioasă este ideală pentru crearea de modele mari, matrițe la scară reală și numeroase prototipuri funcționale.

Opțiuni de personalizare

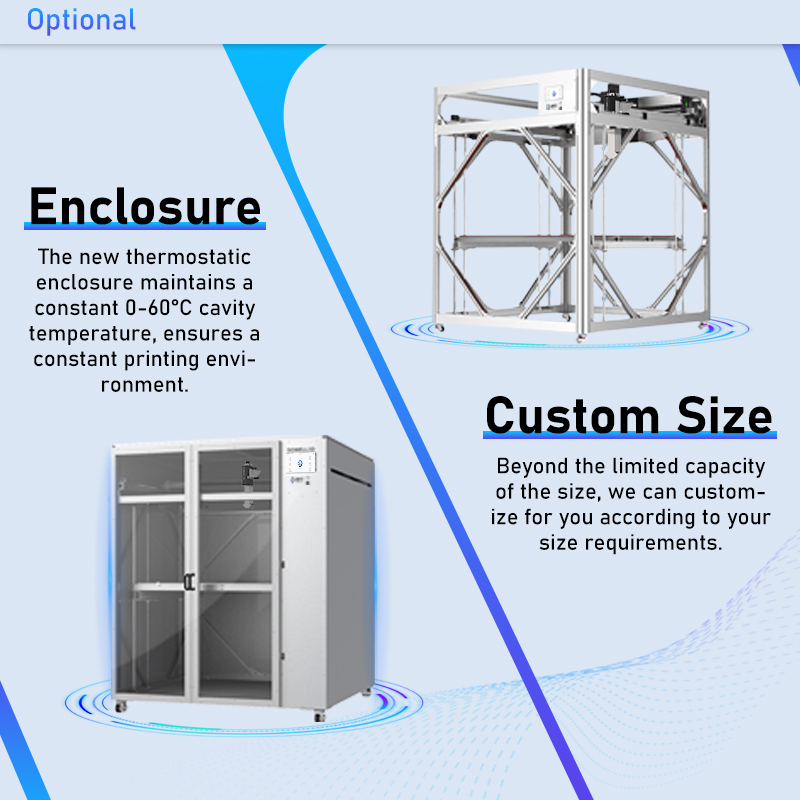

1. Carcasă cu temperatură constantă

Încălzitorul situat în partea de jos a structurii generează un flux uniform de căldură, menținând temperatura în

constantă a camerei la 60°C, prevenind eficient deformarea și deformarea materialelor cu contracție ridicată în timpul imprimării.

2. Dimensiuni personalizate

Pe lângă cele 14 mărimi standard, putem personaliza și mărimea dumneavoastră.

Notificare oficială:

Dragi clienți valoroși,

Acesta este singurul magazin oficial al Luoyang Dowell 3D Electronic Technology Co., Ltd.

Suntem unicul producător și exportator de imprimante 3D Dowell3D și produse conexe.

Vă rugăm să rețineți:

Nu am autorizat niciun site web sau furnizor terț să distribuie sau să revândă produsele noastre.

Produsele vândute sub marca "Dowell3D" pe alte platforme sau site-uri web sunt contrafăcute și neautorizate.

Le lipsește calitatea autentică, asistența tehnică și serviciile post-vânzare. Vă rugăm să fiți precauți și discreți.

la cumpărare.

Alegeți-ne fără ezitare; va fi cea mai bună decizie pe care o veți lua.

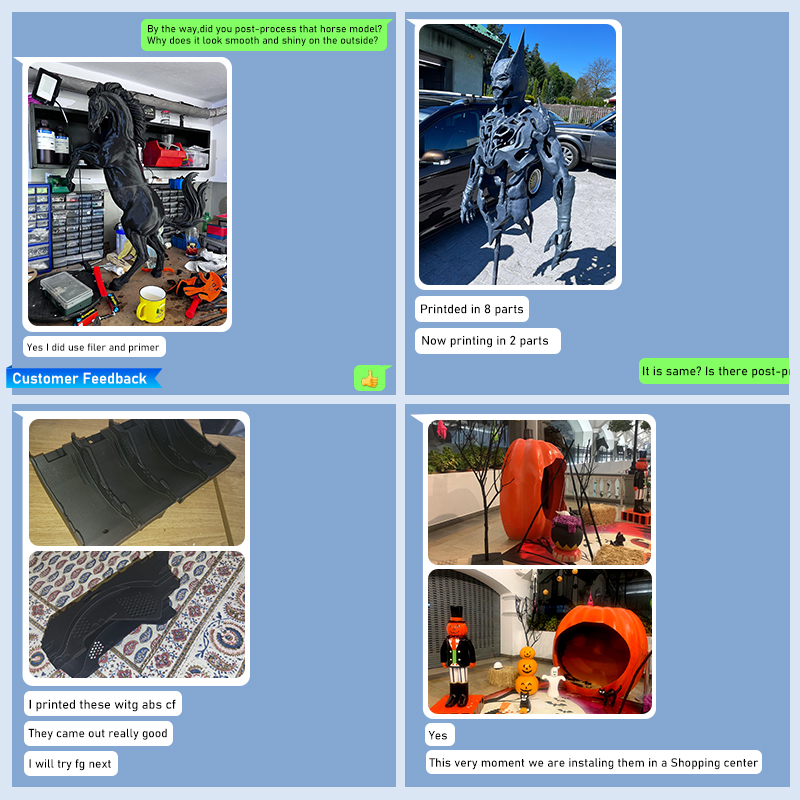

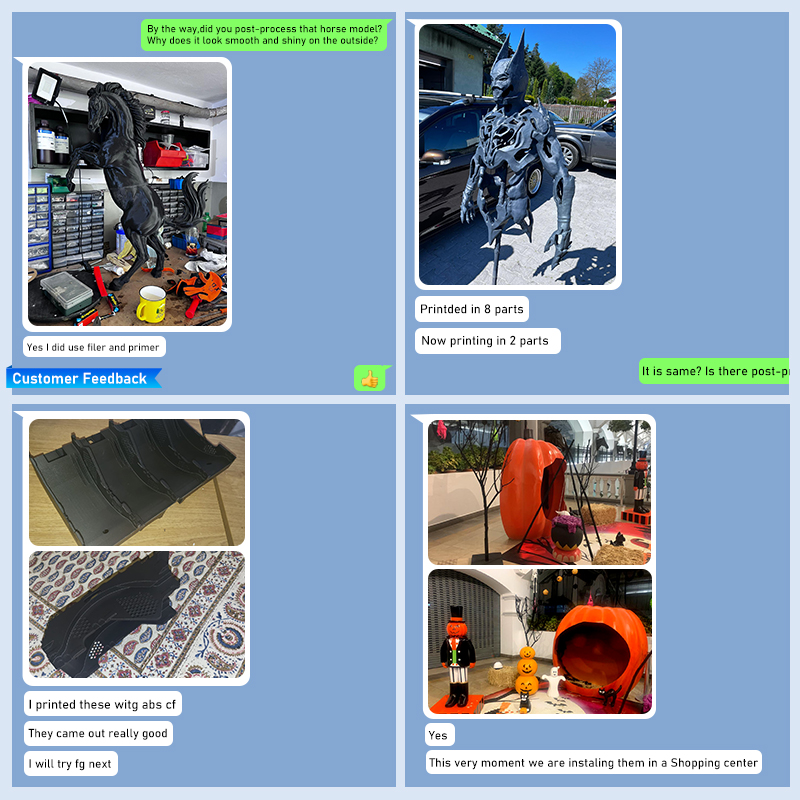

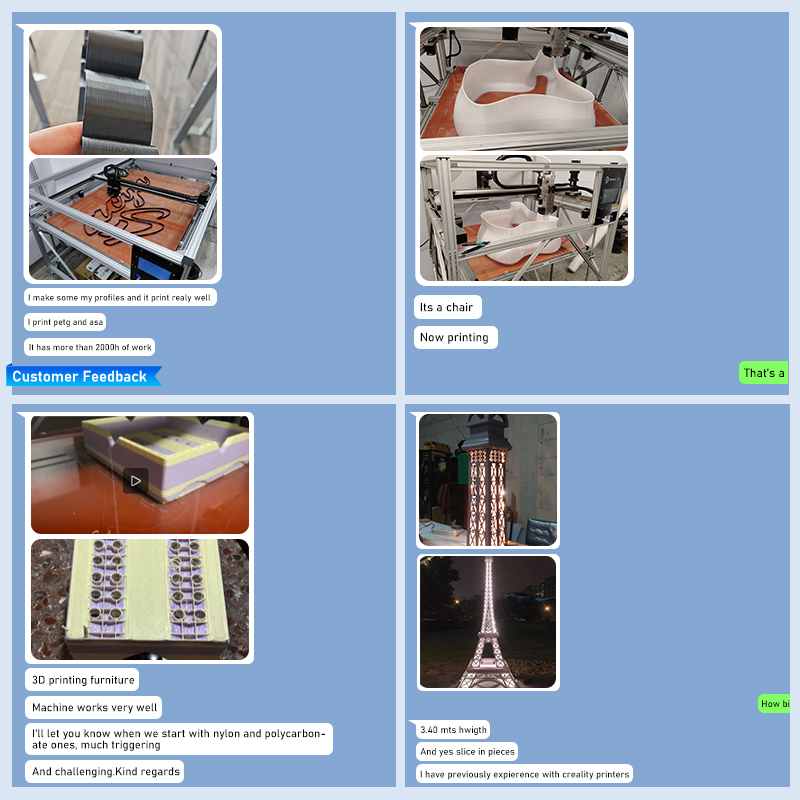

Feedback-ul clienților

De ce să alegeți imprimanta 3D cu peleți FGF?

1. Reduceți costurile

Imprimarea 3D prin extrudare pe peleți oferă economii semnificative, reducând costurile de până la 10 ori în comparație cu filamentul tradițional.

metode bazate pe.

2. Scurtați timpii de livrare

Bucurați-vă de viteze de până la 10 ori mai rapide decât imprimarea 3D convențională cu extrudare a filamentului, reducând drastic timpul de proiectare.

termene de livrare.

3. Proprietăți excelente ale materialelor

Folosește materiale originale pentru proprietăți optime ale materialelor, asigurând performanțe îmbunătățite ale componentelor imprimate

prin calitate superioară.

4. Ecologic

Inovația noastră de imprimare 3D folosește pelete și plastic reciclat mărunțit pentru a crea aditivi sustenabili și ecologici.

alternative de fabricație.

FAQ

1. Sunteți o societate comercială sau un producător?

Suntem DOWELL, un producător de imprimante 3D cu peste 11 ani de experiență în cercetare și dezvoltare.

2. Ce certificări aveți?

CE, FCC, ROHS etc.

3. Aveți software proprietar?

Da, avem o echipă puternică de cercetare și dezvoltare care utilizează software-ul proprietar Dowell și va oferi îndrumări cu privire la modul de utilizare a acestuia.

4. Ce servicii oferim?

Condiții de livrare acceptate: EXW, FOB, CFR, CIF, DDP, DDU

Metode de livrare acceptate: Transport maritim, Transport aerian, DHL, FedEx, UPS

Monede de plată acceptate: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY

5. Există o garanție pentru clienții din străinătate?

Da, mașina vine cu o garanție de un an. Avem ingineri tehnici profesioniști și videoclipuri cu instrucțiuni.

Mașina este complet automată și ușor de utilizat.

6. Cât durează imprimarea unei piese cu imprimanta 3D Dowell FGF?

Timpul de imprimare depinde de materialul, forma și dimensiunea articolului.

Imprimanta 3D Dowell FGF este echipată cu un extruder proprietar și o duză mare, oferind o imprimare puternică și stabilă.

randament de extrudare, rezultând o performanță de imprimare superioară în comparație cu produse similare de pe piață.